Plastic Extrusion Profiles for Beginners

Wiki Article

The Only Guide for Custom Plastic Extrusions

Table of ContentsThe 25-Second Trick For Plastic Extruded ProfilesSome Ideas on Extruded Plastic Profiles You Need To KnowHow Plastic Extrusion Profiles can Save You Time, Stress, and Money.The Only Guide for Extruded Plastic Profiles

As with any kind of production procedure, the extruded profile will certainly differ a little during the process demanding resistances on vital measurements. Resistances on plastic extrusions influence fit and also feature, and also the finest time to begin considering resistance demands is during the initial layout phase. By functioning with Formtech early in the procedure, we can give layout for producing help consisting of resistance demands.For a much more detailed explanation about exactly how tolerances effect pricing, and also a general resistance overview, please click on this link. Bulk thickness is defined as the weight per unit volume of the plastics bought by Formtech for use in custom extrusion applications. Mass density impacts flow and also feed rates on the extruder, as well as variants in bulk thickness of the plastic will trigger variants in size so it is a crucial consideration for personalized extrusion manufacturing operations We talked regarding back pressure above, and also the value of having the ideal quantity of back stress throughout the extrusion process for physical building control (plastic extruded profiles).

When the plastic compound leaves the extrusion die in a pressed type, the substance will certainly kick back, or expand a little. This is described as die swell. Die swell is material specific, implying for instance a plastic (PVC) product will certainly experience a different die swell than a Polyethylene or Polypropylene compound.

In the extrusion process cleaning materials out of barrels, screws and plastic extrusion tooling takes some time and boosts price (https://www.seolinksubmit.com/author/k3ll3rpl4st8/). If material modifications are being made on the line from one work to the next, this might include getting rid of and cleansing the die, pulling the screw on the device to tidy, and brushing out the barrel of the machine while the screws are out.

Some Known Details About Plastic Extruded Profiles

As a matter of fact, the purging products are so stable they can also be left in the extrusion pass away throughout storage space, returned on the extruder the following time the job needs to run, and also began without time consuming cleaning. The typical compound will certainly push the purge out of the die when it leaves.

There are really two methods that can be used to accomplish this feeding procedure - https://gallery.autodesk.com/users/WSM2NARVNGNQWA73?relProf=1. Initially, the material can be consisted of in a receptacle directly over the feed-throat of the extruder and also fed by gravity. The screws will certainly then absorb the optimum quantity of material they can with every revolution of the machine, and this is called flooding feeding.

The trips of the screw are not entirely full of every change of the device. This is called starve feeding of the extruder, and also offers some advantages to the extrusion professional in certain situations. By not filling up the screw network entirely, it supplies more control to the specialist, as well as gets rid of a few other variables that can accompany flood feeding.

Not known Details About Extrusion Of Plastics

For every revolution of a solitary screw device, there is some slippage back over the flights of the screw. This slippage is advantageous for blending of products and colorants, but it develops a possibility for some rising as well as variant with the screw revolution. With this holding true, differing stress as material comes off the screw can create this handling issue for the extrusion service technician.Call today or email at [e-mail safeguarded] to find out more.

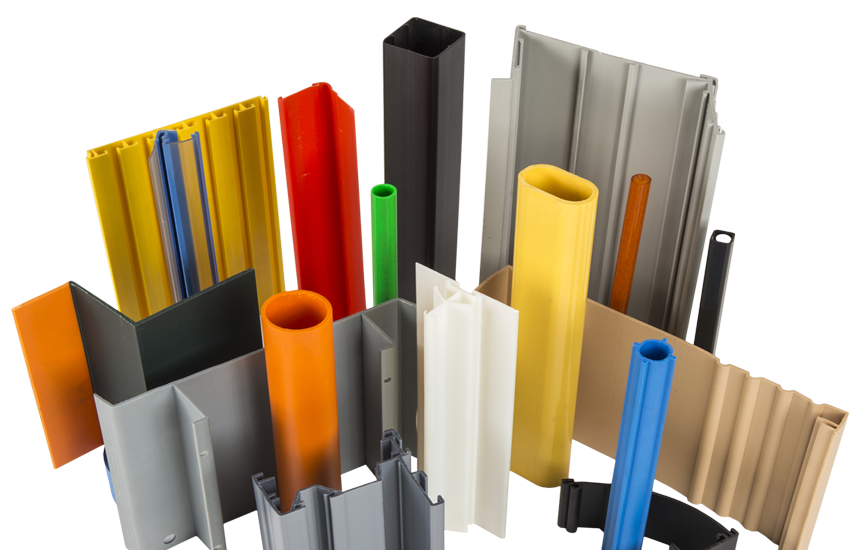

Such a variety of products as well as uses matches to the vast array of compatible materials and also adaptability that the extrusion procedure pays for in producing custom accounts to meet your exact specifications. The plastic profiles developed in the extrusion process can be either versatile or rigid. Both offer advantages for different use situations (https://www.twitch.tv/k3ll3rpl4st8/about).

The Definitive Guide for Plastic Extrusion Companies

While it eventually never ever prospered at its intended function, it nonetheless located regular usage in the automotive market in other methods, many thanks to its high fluid resistance as well as superb sealing efficiency. Automotive components commonly made from Santoprene include climate seals, bumpers, cable television jacketing, as well as a lot more. Santoprene TPV's remarkable securing residential property additionally makes it especially beneficial in construction, where it can be utilized to make window seals, tubes, electric adapters, and caster wheels (custom plastic extrusion manufacturers).We use advanced innovation in order to produce the precise kind of extruded item you require. We are delighted to begin dealing with you quickly!.

Manufacturing high quality items is as vital to us as achieving the greatest criteria for customer care. At the forefront of our service are expert as well as devoted staff members who fulfill everyday challenges with ingenious see page concepts - custom plastic extrusion manufacturers. Consumer e-mail Custom-made accounts/ shapes Dual Products Hollows Rods Tubes Angles Bindings Brackets Caps Programs Clips Edgings Insulators J-Retainers/ J-Clips Moldings Retainers Seals Sleeves Spacers Straps T-moldings Tapes Tracks Cold Temperature Level Performance Color Matched Dual-Durometer Convenience of Setting Up Embossed Flame Retardant Flexible High Gloss Heat Efficiency Interlocking Locking Matte Non-Contact Food Grade Ribbed Snap Fit Stiff Toughness Distinctive Weatherability Aerospace Appliance Air/Water/Pollution Control Automotive Building Products Concrete Building And Construction Electric Lawn & Yard Logistics/ Transport Marine Office Equipments Factor of Purchase (POP) Display Many Providers Can Be Dealt With In-Line to Eliminate Second Workflow Adhesive/Transfer Tape Application Cut to Length Reducing Boring Embossing Warmth Sealing Laminating Punching Directing Slotting Special Product Packaging Welding AIAG Automotive Market Activity Group ASME American Culture of Mechanical Designers ASTM American Society for Screening and Products DOT Department of Transport FDA Fda FMVSS Federal Automobile Safety Requirements MIL-STD Military Specs SAE Society of Automotive Engineers UL Underwriters Laboratories ISO International Company for Standardization.

Report this wiki page